Author Affiliations

Abstract

Beijing Key Lab for Precision Optoelectronic Measurement Instrument and Technology, School of Optoelectronics, Beijing Institute of Technology, Beijing 100081, China

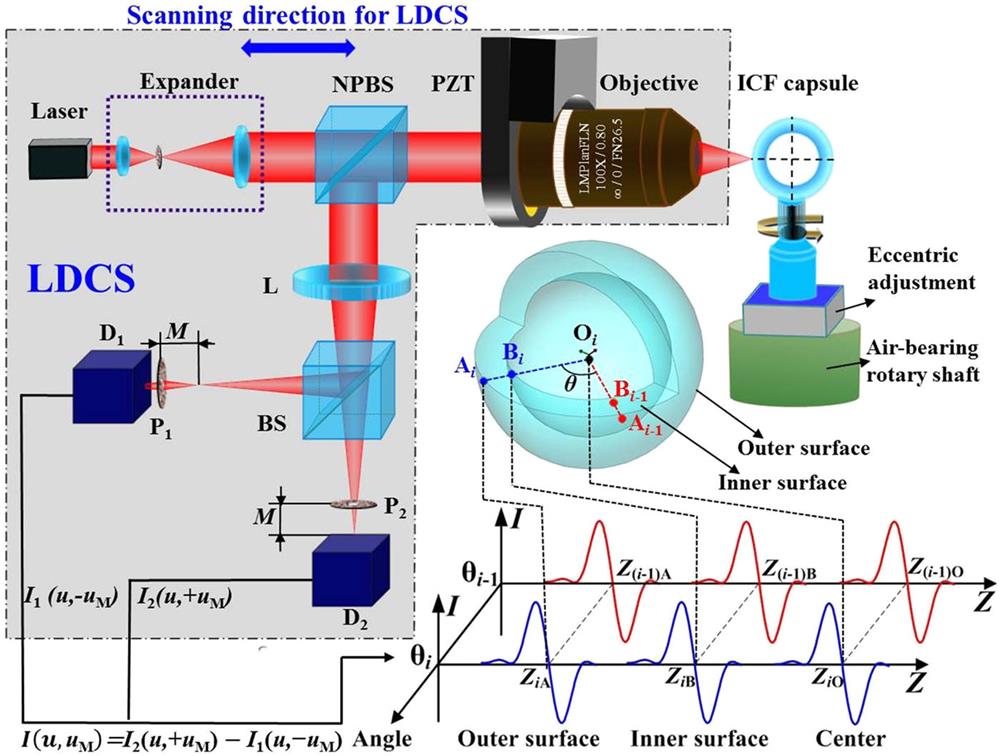

A method based on the laser differential confocal principle is proposed for measurement of the uniformity of the inner and outer radius and shell thickness for an inertial confinement fusion (ICF) capsule. Firstly, this method uses the laser differential confocal measurement system (LDCS) driven by a precision air-bearing slide to scan and measure radially the outer radius, R, inner radius, r, and shell thickness, T, accurately. Secondly, a precision air-bearing rotation system is used to drive the capsule to rotate an angle, θ, in sequence, and the LDCS is used to measure R, r and T at the corresponding angle. Finally, the uniformity of the ICF capsule’s R, r and T can be calculated by the values of R, r and T measured at the position of each rotation angle. This method provides an approach for achieving high-precision, non-destructive, comprehensive, and rapid measurement of the uniformity of the inner and outer radius and shell thickness of an ICF capsule. Preliminary experiments indicate that measurement precision, using the proposed method for the uniformity of the outer radius, shell thickness and inner radius of the capsule, can reach 7.02 × 10?5, 5.87 × 10?4 and 6.52 × 10?5, respectively.

Matter and Radiation at Extremes

2019, 4(2): 025401

为解决激光差动共焦元件参数测量系统中人工调整元件姿态效率低、重复性差的问题, 研制了激光共焦球面元件姿态自动调整系统。基于共焦原理, 建立了元件失调量与电动四维调整机构调整量关系的数学模型, 并根据CCD探测器实时获取的光斑位置信号分析出被测件的姿态信息, 结合闭环反馈控制算法实现姿态自动调整。利用电动四维调整机构搭建了自动调整实验装置, 实验结果表明: 研制的电动调整机构平移调整分辨力达到0.5 μm, 倾斜调整分辨力达到8″; 调整系统能够快速、稳定地将被测件姿态失调量调至误差范围内, 有效提高调整重复性及效率, 对激光差动共焦测量系统实现全自动球面元件参数检测格外重要。

激光共焦 自动调整系统 四维调整机构 球面元件姿态 laser confocal automatic adjustment system four-dimensional adjustment mechanism attitude of spherical component

北京理工大学 光电学院 光学测量研究中心, 北京 100081

为了从海量激光聚变靶丸中高效检测出符合激光核聚变试验要求的靶丸, 提出一种针对靶丸流水式测量的快速筛选技术。所提技术利用机械臂控制显微镜逐一对待测靶丸放大并通过CCD成像, 利用空间矩亚像素细分算法计算出靶丸的亚像素级轮廓信息, 进行圆度评定, 并根据圆度大小对靶丸进行筛选。通过机械臂和靶丸放置盘之间的三维运动配合, 可遍历测量所有待测靶丸。经过理论及实验证明该方法空间分辨力优于0.51μm, 可快速、精确地对海量靶丸进行初步筛选。

应用光学 聚变靶丸 快速筛选 亚像素细分 applied optics ICF Shells rapid screening sub-pixel